STEp 1. CAD

Having the equipment in house means we are in full control and our versatility is endless. From start to finish we offer a bespoke service worldwide.

CAD

Start off by using our CAD software, whether it is to simply import the drawing from you, or to create it ourselves.

Step 2. Splitting

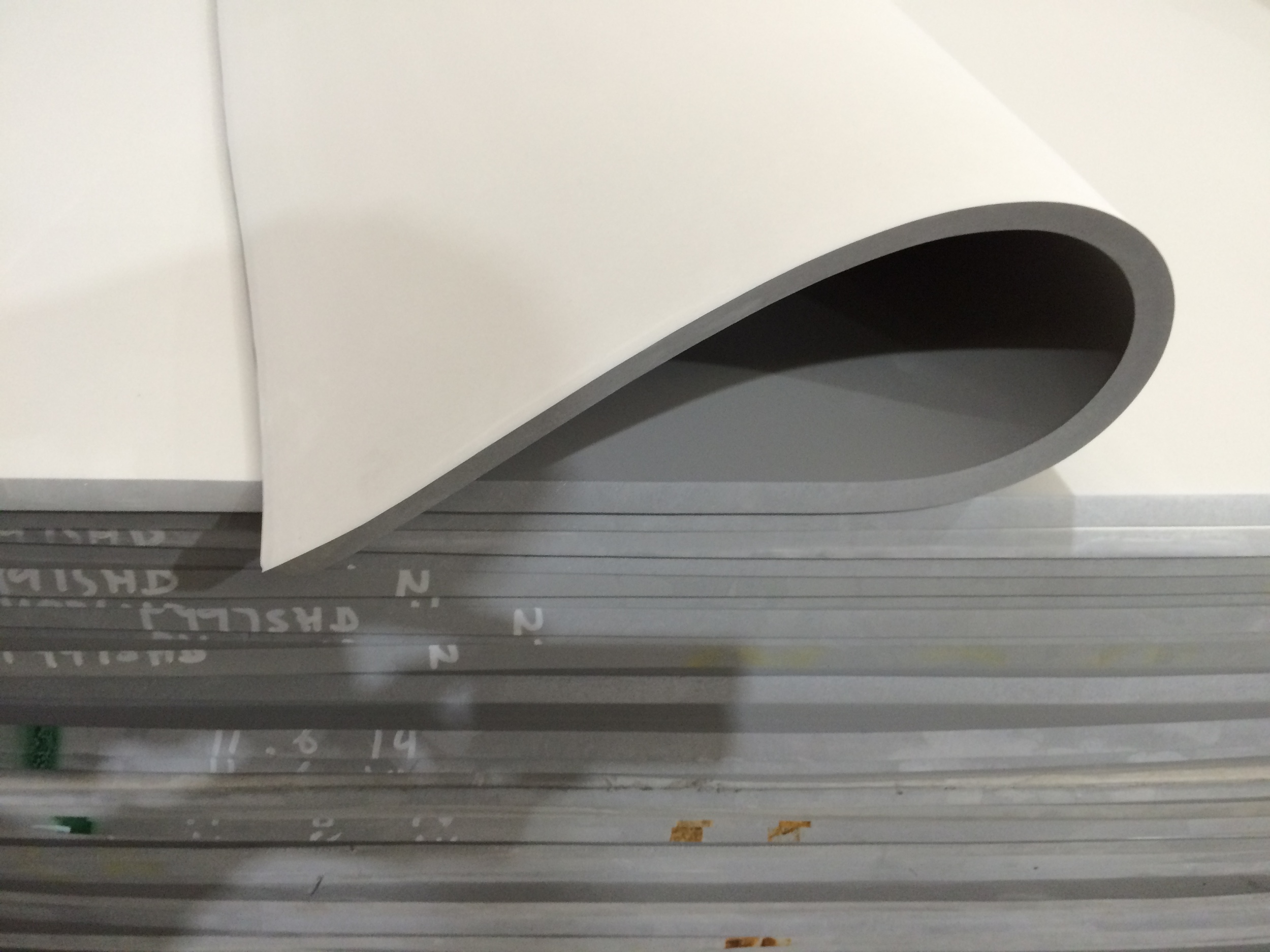

Our Splitting machines enable us to convert rubber from blocks and sheets to a specific thickness.

One of two of our Splitting machines

Step 3. Water-jet/CNC Routing

Once we have drawn the files and split the material it is on to the penultimate stage of our service; the cutting.

There is not a lot these machines can’t do; from rubber, plastic, wood or metals we have you covered, 1mm to 100mm thick and the most complex shapes are all well within our capabilities between these machines.

The Kimla CNC Router

Waterjet Head and freshly cut pieces

Step 4. Packed and sent

The final stage of our service is to pack it up in one of our branded boxes and ship it on Fedex to your chosen destination.